My standard focus motors are designed for typical astrophotography needs, meaning that accuracy and high capacity (for heavy duty focusers and large cameras) are more important than speed. But recently, a friend asked me to make a motor for visual use. Using a focus motor for visual observing can actually be very helpful because it allows you to adjust focus without touching the telescope, thus avoiding the vibrations that generally happen when you touch a telescope. The rotary knob on the PerfectStar family focus controllers makes for a very easy transition from direct focusing to motorized focusing. Backlash compensation also makes it less frustrating to get precise focus, and (theoretically) you could use temperature compensation to avoid ever having to re-focus. In practice, temperature compensation is not so useful because most visual observers change eyepieces frequently, and you could never get all your eyepieces sufficiently “parfocal” that you don’t need to adjust focus slightly when changing them.

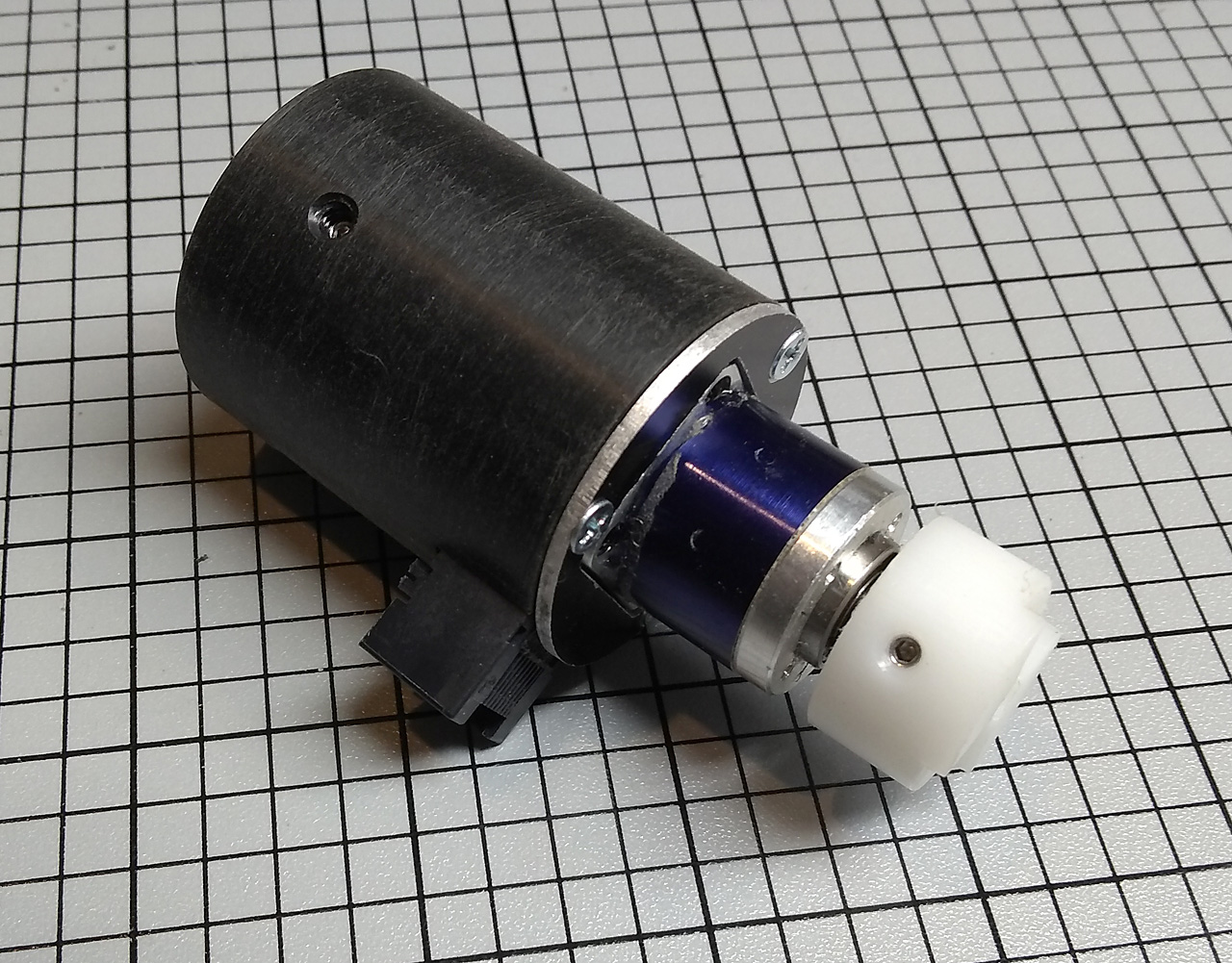

At first we tried a standard motor, but it was just too slow for visual use. Some of my standard motors are faster than others, and the final speed also depends on the characteristics of the telescope, but in this case we needed something much faster. I had been wanting to try a different type of motor anyway, so found one with suitable specifications and ordered it. From China. A month or so later (!) it arrived, and after a quick test to make sure it worked with my PerfectStar B controller, I fabricated a housing for it. Because the motor is long, I couldn’t use my standard enclosure, which is an aluminum box. But the motor is small enough that it fits inside the plastic (Delrin) tube I use to attach the motor assembly to the telescope. Here’s it is with the front piece removed:

Setscrews in the Delrin tube hold the motor in place. The tricky part was finding a place for the connector to sit. The connector is the square-ish piece sticking out from the side in the middle of the motor assembly. The solution was to cut a notch in the rear housing to fit the base of the connector (which is where the motor wires connect), then cut an aluminum disc that is attached to the rear housing with 3 screws to clamp the connector in place. For greater security, there is also a setscrew on one side of the connector.

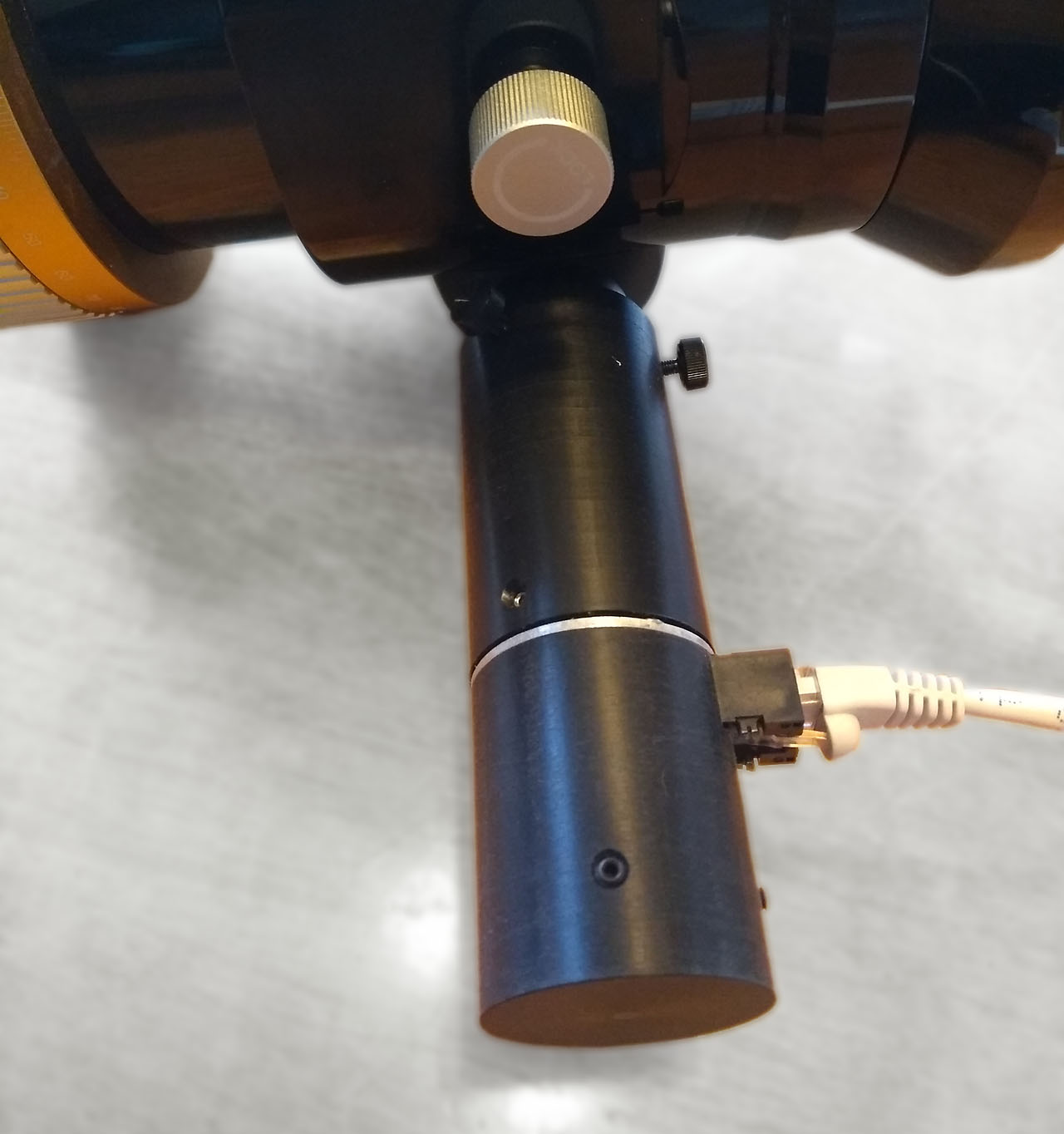

When the whole thing is attached to a telescope it looks like this:

The motor assembly can be attached at any rotation you like, thus allowing the the cable to come off in the desired direction. It’s a bit longer than any of my standard motors, but less than an inch, really. The perspective in the above photo makes it look longer than it really is.

It works beautifully, moving at least 8 times as fast as my fastest standard motor, and as much as 20 times the slowest. I probably would not recommend this particular motor for astrophotography, but there are similar motors with more torque that would work great. The cost is similar to my standard motors, or a bit lower. However, it can take a long time to get them. So I don’t plan to add this to the line-up of standard products, but I’m happy to make one for any customer that wants it.